Optimal Conditions for Concrete Polishing

Concrete polishing is most effective when performed under optimal environmental conditions. Temperature and humidity levels significantly influence the curing process and the quality of the finish. Ideally, the temperature should be between 60°F and 80°F, with low humidity to ensure proper curing and adhesion of the polishing compounds.

Spring and fall are considered the best seasons for concrete polishing due to moderate temperatures and humidity levels, which support optimal curing and finish quality.

Avoid polishing during extreme cold or heat, as temperature fluctuations can cause cracking or uneven surfaces. Consistent weather conditions help achieve a smooth, durable finish.

Scheduling during periods of low rainfall and stable weather ensures minimal disruptions and optimal curing conditions for the concrete surface.

Indoor projects can be scheduled year-round, provided temperature and humidity are controlled. Outdoor projects benefit from seasonal planning to avoid weather-related issues.

A technician uses specialized equipment to grind and polish the concrete surface, revealing a smooth, glossy finish.

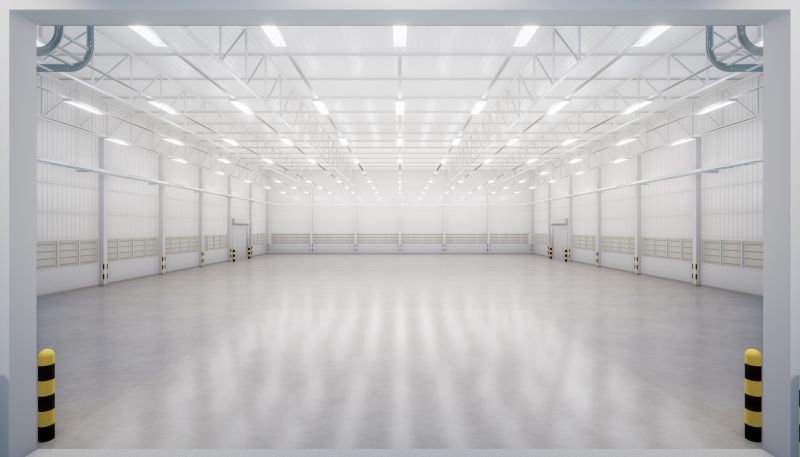

Indoor spaces are polished in controlled environments, ensuring consistent results regardless of season.

Outdoor surfaces require scheduling during favorable weather to prevent surface damage and ensure durability.

Finished floors exhibit high reflectivity and durability, suitable for commercial and industrial settings.

Concrete polishing enhances the durability, appearance, and maintenance of concrete floors. The process involves grinding the surface with progressively finer abrasives to achieve a smooth, glossy finish. This method is popular for commercial, industrial, and residential spaces due to its cost-effectiveness and aesthetic appeal. Proper timing ensures the surface is cured and stable, which is essential for achieving optimal results. Statistics indicate that polished concrete can last for decades with minimal maintenance, making it a cost-efficient choice over the long term.

A high-gloss finish enhances the aesthetic appeal of retail and office environments.

Durable and resistant to wear, suitable for warehouses and factories.

Adds a sleek look to basements, garages, and kitchens.

Proper prep is vital for achieving the best finish and longevity.

Scheduling concrete polishing during suitable weather conditions ensures a high-quality, long-lasting finish. Proper curing and surface preparation are critical steps that influence the final appearance and durability. When planned correctly, polishing can significantly improve the surface's aesthetic and functional qualities, making it an advantageous investment for various property types.

A reflective, smooth surface ideal for high-traffic areas.

Advanced machinery achieves precise grinding and polishing.

An elegant finish suitable for commercial spaces.

Adequate curing ensures optimal polishing results.

Interested parties should consider scheduling their concrete polishing project during periods of stable weather to maximize results. Proper planning and timing contribute to a durable, visually appealing finish that maintains its quality over time. For further details or to arrange a consultation, filling out the contact form is recommended.